- Electric Hammer[10]

- Springs[2]

- Magnetic Materials[1]

- Refrigeration & Heat Exchange Parts[1]

- Nickel[6]

- Other Metals & Metal Products[3]

- Electrical Wires[2]

- Copper Strips[2]

- Metal Building Materials[6]

- Other Home Appliances[1]

- Copper Wire[6]

- Other Copper[1]

- Electric Heater Parts[1]

- Other Steel Products[1]

- Insulation Materials & Elements[1]

- Wiring Harness[1]

- Contact Person : Ms. zhou ruth

- Company Name : Danyang Hualong Superior Steel Co., Ltd.

- Tel : 86-511-86450506

- Fax : 86-511-86453363

- Address : Jiangsu,DANYANG,YUNHE TOWN

- Country/Region : China

- Zip : 212352

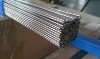

Inconel 718

Inconel 718diameter: 10-250mm(bar), 0.1-8 wireGrades: Inconel600, 601, Inconel x-750, Inconel 718,hastelloy B, c276 as so on

Inconel 718 Chemical composition

Alloy | % | Ni | Cr | Fe | Mo | Nb | Co | C | Mn | Si | S | Cu | Al | Ti |

718 | Min. | 50 | 17 | balance | 2.8 | 4.75 | 0.2 | 0.7 | ||||||

Max. | 55 | 21 | 3.3 | 5.5 | 1 | 0.08 | 0.35 | 0.35 | 0.01 | 0.3 | 0.8 | 1.15 |

Inconel 718 Physical properties

Density | 8.2 g/cm³ |

Melting point | 1260-1340 °C |

Inconel 718 Alloy minimum mechanical properties in the roomtemperature

Alloy | Tensile strength Rm N/mm² | Yield strength R P0. 2N/mm² | Elongation A 5 % | Brinell hardnessHB |

Solution treatment | 965 | 550 | 30 | ≤363 |

718 Characteristic as below1.workability2.High tensile strength,endurance strength,creep strength and rupture strength at 700°C. 3.High inoxidability at1000°C.4.Steady mechanical performance in the low temperature.5.Good welding performance.

Inconel 718 Metallurgical structure 718alloy is Austenitic structure, precipitation hardening generate "γ" made it excellent mechanical performance. G rain boundary generate "δ" made it the best plasticity in the heat treatment.

Inconel 718 Corrosion resistance 718 alloy with extremely resistance to stress corrosion cracking and pitting ability in high temperature or low temperature environments, especially the inoxidability in the high temperature.Inconel 718 Application fieldThe elevated temperature strength, excellent corrosion resistance and workability at 700°C properties made it use in a wide range of high requirement environments. 1.Steam turbine2.Liquid-fuel rocket 3.Cryogenic engineering 4.Acid environment 5.Nuclear engineering

Inconel 718